Innovation is the key to success in the field of electronics. As demands for smaller, more flexible, and higher-performance electronic devices increase companies are constantly searching for new ways to innovate the process of assembly. One such groundbreaking technology that has received a lot of attention is manufacturing with flex circuits.

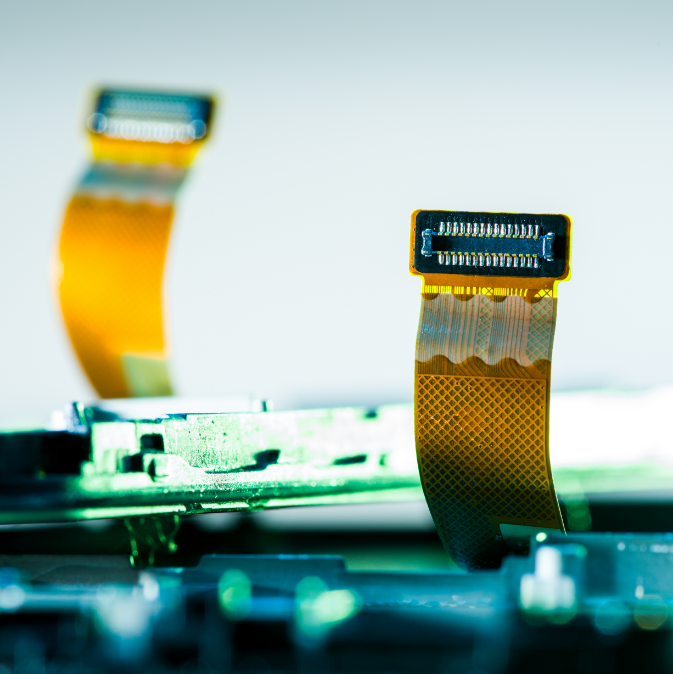

Flexible circuits are also known as flexible printed circuit boards (PCBs) and offer many benefits over rigid PCBs. These circuits bend, twist and conform to different forms. They are great for applications requiring complex designs, a limited amount of space or a greater durability.

Flex circuits help manufacturers extend the boundaries of design by providing an adaptable base that adjusts to the form of the product. This flexibility enables the creation of more compact and imaginative designs and ultimately results in lighter and smaller products. Imagine a smartphone that is curved around your hand a wearable health tracker that fits comfortably around your wrist, or even a smart appliance with a sleek, ergonomic design. Designers and engineers can turn their visions into reality with Flex Circuits, enabling them to open a whole world of new possibilities for designing products.

Flex circuits are durable and provide more aesthetic benefits. Traditional PCBs can be damaged by shock, vibration or repeated bent. Flex circuits, however, have materials that resist these elements, making them highly reliable. This kind of durability is essential in the fields of aerospace, automotive and medical, in which electronic components must endure extreme conditions and not compromise their performance.

The capabilities of flex circuits are significantly increased by the manufacturing methods used. Flexible circuits, in contrast to rigid PCBs are made of a flexible material like polyimide or polyester. The substrate is the base of the circuit. It allows the circuit to be bent, twisted and maintain electrical connections. Flex circuit manufacturers are able to precisely etch circuit trace, connect complex interconnects and integrate components on the flexible substrate by leveraging the latest manufacturing techniques.

Surface mount technology (SMT) allows components to be mounted directly on the flexible circuit. This increases flexibility and functionality. SMT allows manufacturers to mount electronic components directly on the surface of the device that is a flex circuit. This eliminates the need to use bulky connectors, and reduces the dimension of the device. This method is not just efficient and enhances signal integrity, but also reduces weight and enhances thermal control.

The flex circuit manufacturing techniques can also be used to create rapid prototypes and is scalable to meet the requirements of larger numbers. The flexible nature of circuit designs allows for rapid iterations during the prototyping phase, which speeds up the product development cycle. Due to their capacity to be produced in high volumes by using automated manufacturing processes, flex circuits provide cost-effective solutions for large-scale production. This makes flexible circuits a great choice for businesses looking to bring innovative ideas to the market quickly and efficiently. For more information, click flex circuit manufacturer

The availability of dependable flex-circuit manufacturers is growing increasingly important as the demand for electronic devices that are flexible continues to grow. Collaborating with experienced and reputable manufacturers is crucial for ensuring the quality, precision, and consistency in the manufacturing of flex circuits. These manufacturers have the knowledge and expertise to help you through the process of designing they can provide invaluable insight into choices of material and ensure that it is in line with industry standards.

Flexible circuits are the essential component to reach the highest levels of complexity in modern electronic assemblies. They are at the core of various complex systems, ranging including displays in consumer products to military applications. Since they are fluidly moving across small areas, flexible substrates offer engineers the ability to design their designs with a variety of features and still fit into small footprints for assembly. Although a variety of other kinds of circuit routing are available, their mechanical and electrical properties simply can’t compare to those offered by flexible assemblies when it comes to having to meet the strict size limitations. When you need complex interconnections that blend several technologies into a carefully designed package, using flexible circuits is far far the most effective choice.